Our specialty!

VA Fabrication BV

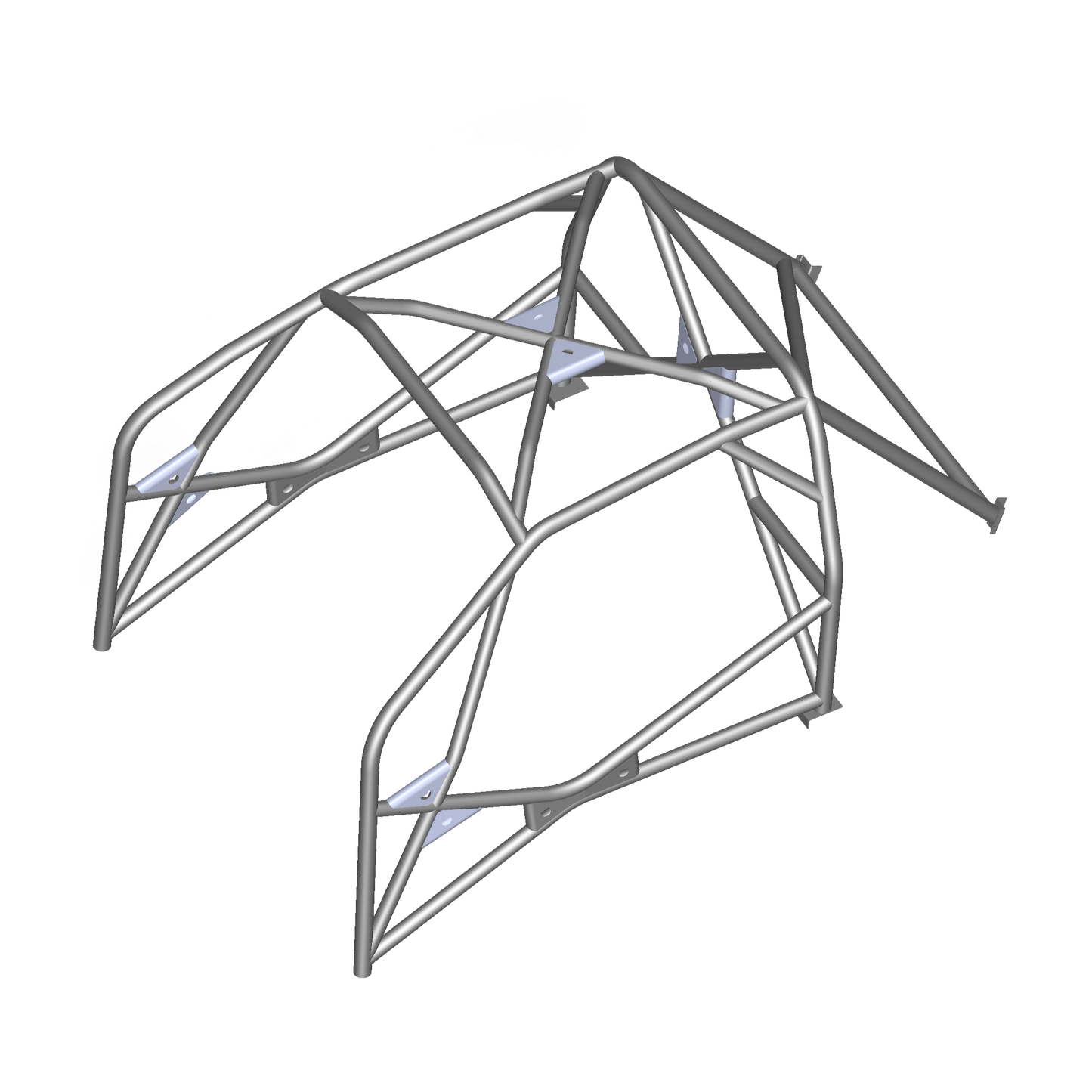

Fia approved custom roll cage, starting price

€2.500,00

€2.500,00

Sale

Sold out

With over 30 years of experience in producing roll cages, VA Fabrication BV is the expert in roll cages for race and rally cars, rally trucks and side by side buggies. We work exclusively with high-quality materials, such as Chrome Molybdenum (25CrMo4). We understand that every driver has unique requirements. We offer custom-made roll cages that meet the strictest safety standards and regulations. Whether you are looking for a one-off roll cage for your personal race car, a complete series for a full race cup, or extremely lightweight roll cages that deviate from the Homologation Regulations, we have the expertise to meet your needs. All our roll cages can be built including certification by the Dutch ASN: the KNAF. We use advanced 3D scanning technology to ensure that our roll cages fit perfectly.